Fasteners and Machining: Necessary Components for Accuracy Production

Fasteners and Machining: Necessary Components for Accuracy Production

Blog Article

Grasping the Art of Fasteners and Machining: Technologies and Best Practices

In the world of industrial manufacturing and design, the proficiency of fasteners and machining is a cornerstone of guaranteeing structural honesty, functionality, and long life in numerous applications. Join us as we check out the latest innovations and delve into the nuanced world of understanding fasteners and machining, discovering essential insights and approaches that can boost your technique to engineering services.

Evolution of Attachment Technologies

Throughout the commercial transformation and right into the modern-day period, the advancement of attaching technologies has actually been noted by continual advancements in effectiveness and dependability. Fasteners, such as rivets, screws, and screws, play a crucial role in various industries, including automobile, aerospace, building, and electronic devices. The demand for more powerful, a lot more sturdy, and easier-to-install fastening remedies has actually driven technology in the field.

One substantial development has actually been the change in the direction of precision machining techniques to produce fasteners with greater tolerances and remarkable efficiency. This shift has actually allowed manufacturers to create fasteners that fulfill rigid quality standards and deal boosted resistance to corrosion and exhaustion.

Additionally, the introduction of sophisticated products, such as titanium alloys and compounds, has reinvented the capacities of fasteners. Fasteners and Machining. These products provide exceptional strength-to-weight ratios, making them suitable for applications where reducing weight is crucial without jeopardizing structural stability

Advancements in Machining Techniques

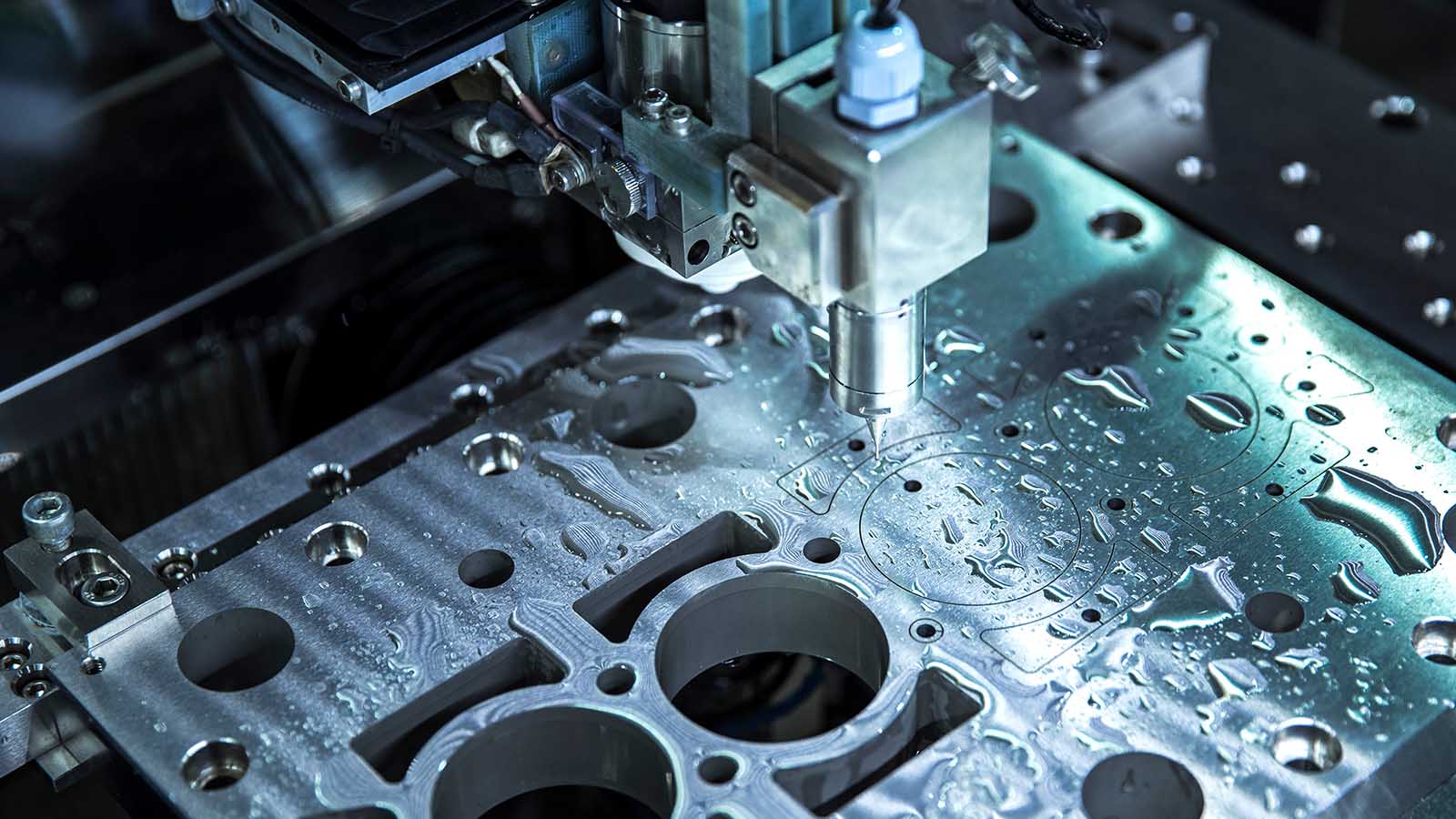

In the world of industrial production, the continual development of machining methods has actually paved the method for unprecedented precision and performance in the production of bolts. This specific control makes it possible for manufacturers to produce facility and detailed fastener layouts with convenience.

Additionally, the adoption of multi-axis machining facilities has actually enabled synchronised reducing operations from different angles, additionally improving effectiveness and minimizing production times. By utilizing these innovative machining approaches, producers can fulfill the increasing demand for high-quality fasteners while preserving cost-effectiveness in their procedures.

Selecting the Right Bolt Products

Selecting the suitable product for bolts is an essential choice that significantly impacts the performance and durability of the constructed components. When picking the best bolt product, numerous variables should be taken into consideration to ensure the resilience and dependability of the end product. The product picked should be compatible with the ecological conditions the bolts will be subjected to, such as temperature level variants, moisture levels, and harsh elements.

Usual products utilized for fasteners include stainless steel, carbon read more steel, light weight aluminum, and titanium, each offering special homes that suit different applications. Carbon steel is an economical option ideal for numerous general-purpose applications.

Enhancing Accuracy in Machining

Attaining optimum precision in machining is necessary for guaranteeing the high quality and efficiency of machined parts. Precision in machining refers to the capacity to consistently produce parts within limited tolerances and with high accuracy. To improve precision in machining, manufacturers use a selection of advanced methods and innovations. One trick technique is utilizing Computer system Numerical Control (CNC) equipments, which offer remarkable accuracy and repeatability compared to conventional hands-on machining methods. CNC machines are programmable and can execute complex machining procedures with minimal human treatment, leading to higher find more info precision levels.

Along with CNC machining, making use of advanced cutting tools and tool holders can also considerably boost precision. Top quality cutting tools with sophisticated finishings lower friction and wear, leading to a lot more specific cuts and dimensional accuracy. Additionally, executing stringent high quality control actions throughout the machining procedure, such as routine evaluations and calibration of devices, assists preserve regular precision degrees. By focusing on accuracy in machining, suppliers can achieve remarkable item top quality, tighter resistances, and enhanced general performance of machined parts.

Finest Practices for Bolt Installation

Precision in machining plays pop over here a crucial duty in ensuring the reliability and longevity of fastener setups. When it comes to finest techniques for bolt installment, one essential facet is the correct option of fasteners based on the certain application needs.

Moreover, ensuring that the fastener threads are totally free and clean of particles before installment is crucial to accomplishing a safe and effective link. By sticking to these best methods, manufacturers can optimize the stability and efficiency of their fastener installments.

Verdict

By selecting the best bolt materials and improving precision in machining, makers can accomplish ideal results in their operations. Generally, grasping the art of fasteners and machining involves continuous advancement and adherence to ideal methods.

In the world of industrial manufacturing, the continual evolution of machining approaches has paved the means for unmatched precision and performance in the production of fasteners.Precision in machining plays a crucial role in guaranteeing the dependability and durability of fastener installations. When it comes to best practices for fastener installment, one essential element is the appropriate option of fasteners based on the particular application needs. By selecting the right bolt materials and improving accuracy in machining, suppliers can accomplish optimal outcomes in their procedures. Overall, grasping the art of fasteners and machining involves continuous development and adherence to finest methods.

Report this page